LI-BE Gruppi Volventi has been designing, manufacturing and selling cylindrical rollers and ball bearings of special design and execution since 1984.

The range of production includes bearings, rollers and complementary articles (slides and plates) used in the sector of internal goods handling, metallurgical machinery, painting machinery, power transmission unit, rotating tables for tool machines, etc.

LI-BE has always been synonymous with special bearings and is the holder of some international patents. For this reason the company uses a team of experts who are capable of providing solutions and projects which are suited to customers’ specific requirements.

Thanks to FEA and to the use of internal software we can have a more clear idea of the consequences of the loads on the bearings. A knowledge that, until a few years ago, was belonging to the most re-known manufacturers only.

Notwithstanding its hard-won position as market leader and aware of the rugged competition existing in its industry, LI-BE has never taken its attention off the niche market which are open to those companies that take flexibility, readiness, experience and reliability their strong points, as LI-BE does.

Notwithstanding its hard-won position as market leader and aware of the rugged competition existing in its industry, LI-BE has never taken its attention off the niche market which are open to those companies that take flexibility, readiness, experience and reliability their strong points, as LI-BE does.

Our know-how, the high quality of our products and the will to stand out in a more and more demanding industrial environment, make LI-BE the right partner for those who aim at high technological solutions.

For more info about LI-BE and its products please visit www.li-be.com

Back-up Rolls

LI-BE is a specialized company able to design and manufacture back up bearing for different kind of steel levelers. As per machine builders or customers demands LI-BE can design the back-up rolls or solve existing problems with its great experience in the field.

Bearings for screw drives

SEL F : Angular contact ball bearings with holes for screw mounting

SEL N : Angular contact ball bearings

SEL Z : Combined roller bearings

SEL ZF: Combined roller bearings with holes for screw mounting

SEL ZFL: Combined roller bearings with holes for screw mounting

SEL ZL: Combined cylindrical roller bearings with extended washer

Chain Pulleys

Chain pulleys with balls for medium and low loads

Chain pulleys for heavy applications

Chain pulleys for light applications

Combined Bearings with Cylindrical Rollers

Adjustable combined bearings with cylindrical rollers

Combined bearings adjustable by screw for steel sections

Combined bearings for heavy loads

Combined bearings for high loads with axial support

Combined bearings for high speeds

Combined bearings for inclined sections

Combined bearings for steel sections

Combined bearings adjustable from outside for steel sections

Full Complement Radial Cylindrical Roller Bearings

Full complement cylindrical roller bearings incorporate the maximum number of rollers and, as a rule, have a low sectional height in relation to their width.

This produces an extremely high load carrying capacity and permits space saving designs to be achieved; however full complement cylindrical roller bearings cannot operate at same high speeds as cylindrical roller bearings of the conventional caged type. Some of these bearings are more suitable for axial loads than high radial loads. All the components form a unit ready for assembling.

- MCF : Full complement cylindrical roller bearings with snap ring housing

- MRC : Radial cylindrical roller bearings full complement, fixed bearings

- MRCF: Radial cylindrical roller bearings full complement, back bearing

- MRF : Radial cylindrical roller bearings with snap ring housing

Radial Cylindrical Roller Bearings, More Roller Sets

Cylindrical roller bearings with four or more rows of rollers are used almost exclusively for rolling mills.

They have lower friction than other roller bearings and can be successfully used where high-speed operation is called for. The low cross-sectional height of cylindrical roller bearings means that the roll necks can have large diameter in relation to the roll itself. In four rows cylindrical roller bearings, the rollers are guided between integral or not-integral flanges on the outer ring.

The inner ring is without flanges; the bearing within certain limits can therefore accommodate axial displacement of the shaft with respect to the housing.

Depending on the application, four rows cylindrical roller bearings can be supplied with a cylindrical bore or tapered bore. The inner or outer ring may be in one piece or in more than one piece.

Types radial cylindrical roller bearings can be listed as below:

- Radial cylindrical roller bearings, four rows with cylindrical bore

- Radial cylindrical roller bearings, four rows with tapered bore

- Radial cylindrical roller bearings, six rows with cylindrical bore

Rotary Table Bearings

The main characteristics of this type of combined bearing are: high running precision, high rigidity at tilting moments and high carrying capacities. These features together with the wide dimensional range make this bearing the right solution for rotary tables, swivel heads, measuring instruments and automation systems.

The bearing is made of two axial needle cage assemblies while the radial part is full complement. The washer, the inner ring and the outer ring have holes to allow mounting by screws.

These bearings can be re-lubricated through the inner ring and the outer ring. They are supplied with grease lubrication. Types of rotary table bearings are:

– SEL Y : Axial-radial bearing, high running precision

– SEL/Y.AV : High speed axial radial bearings

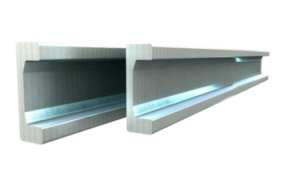

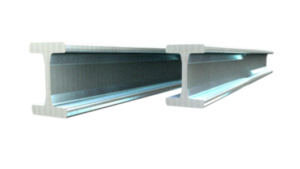

Steel Sections for Combined Bearing Applications

Composed sections for heavy mast applications

These sections are completely machined on the surfaces in contact with the bearings. This guarantees a perfect coupling with the rollers and very little clearances.

RAW MATERIAL: Steel UNI Fe 510C / DIN St 52-3 U / EN 10025 (S355J0) / W Nr. 1.0553

Hot rolled steel section with C shape

Hot rolled steel sections meet most of the technical requirements that arise when designing equipment for goods handling.

RAW MATERIAL: Steel UNI Fe 510C / DIN St 52-3 U / EN 10025 (S355J0) / W Nr. 1.0553

Hot rolled steel section with double T shape

Hot rolled steel sections meet most of the technical requirements that arise when designing equipment for goods handling.

RAW MATERIAL: Steel UNI Fe 510C / DIN St 52-3 U / EN 10025 (S355J0) / W Nr. 1.0553

Sections can be supplied in fixed lengths up to 8 meters and, if required, provided with the housing hole for the stud of the bearing and with milled end for easier jointing with section’s stages.

Stud Type Track Rollers

These types of bearings mainly used for moving or handling different loads. They can be installed in conveyors, material moving cars, etc.

RAW MATERIALS

Outer rings: Steel UNI 18NiCrMo5 casehardened and tempered with final hardness 62-2 HRC

Stud: Steel UNI 18NiCrMo5-20MnCr5 casehardened and tempered with final hardness 60±2 HRC

Thrust Washers: Steel UNI 20MnCr5 casehardened and tempered with final hardness 60±2 HRC

Rolling elements: Steel UNI 100Cr6 hardened and tempered with final hardness 62±2 HRC